DHP 3.0 Axial Piston Pump - High-Pressure Water Treatment Consumables for Industrial Reverse Osmosis/Seawater Desalination

Produktdetails:

| Herkunftsort: | China |

| Markenname: | Fenigal |

| Zertifizierung: | CE |

| Modellnummer: | DHP 3.0 |

Zahlung und Versand AGB:

| Min Bestellmenge: | 1 PC |

|---|---|

| Preis: | verhandelbar |

| Verpackung Informationen: | Standard -Exportpackung |

| Versorgungsmaterial-Fähigkeit: | 60000 Einheiten pro Monat |

|

Detailinformationen |

|||

| Produktmodell: | DHP 3.0 | Geometrische Verschiebung: | 17,7 cm³/rev |

|---|---|---|---|

| Nennstrom bei 3000 U / min: | 3,0 m³/h (äquivalent zu 50 l/min) | Mindestauslassdruck: | 20 bar |

| Maximaler Ausgangsdruck: | 80 bar | Mindestdurchgangsdruck: | 1 Bar |

| Maximaler kontinuierlicher Einlassdruck: | STANGE 5 | ||

| Hervorheben: | DHP 3.0 axial piston pump,high-pressure water treatment pump,industrial reverse osmosis pump |

||

Produkt-Beschreibung

Core Technical Parameters of DHP 3.0

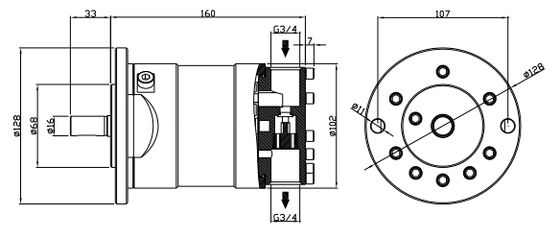

Inlet & Outlet Dimensions of DHP 3.0

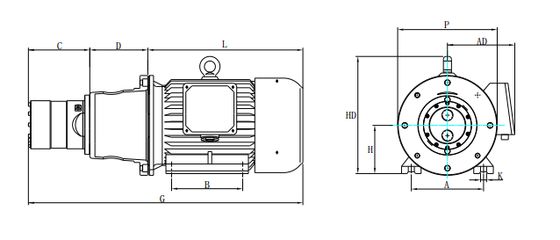

Overall Dimensions of DHP 3.0 (Unit: mm)

Manufacturer Contact Information

![]()

Möchten Sie mehr über dieses Produkt erfahren?