Veolia E-Cell MK-3 Mini HT EDI module for pharmaceutical ultrapure water production

Produktdetails:

| Herkunftsort: | CHINA |

| Markenname: | VEOLIA |

| Zertifizierung: | CE |

| Modellnummer: | Veolia edi Mk-3Miniht |

| Dokument: | FSpwE-CellMK-3MiniHT_EN.pdf |

Zahlung und Versand AGB:

| Min Bestellmenge: | 1 PC |

|---|---|

| Preis: | verhandelbar |

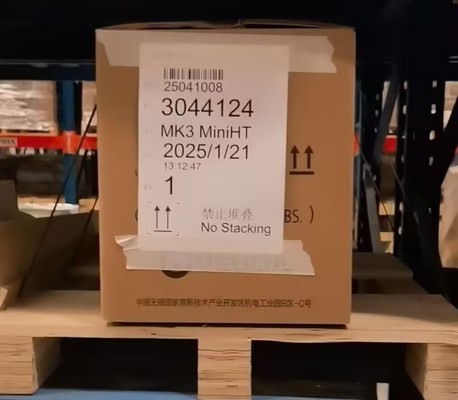

| Verpackung Informationen: | Standard -Exportpackung |

| Lieferzeit: | 1 Monat |

| Zahlungsbedingungen: | T/t |

| Versorgungsmaterial-Fähigkeit: | 60000 Einheiten pro Monat |

|

Detailinformationen |

|||

| Miniht -Durchflussratebereich: | 0,5–1,6 m3 /h (2,2–7,0 gpm) | Miniht Produktversandgewicht: | 57 kg (126 lbs) |

|---|---|---|---|

| Miniht -Abmessungen dieses Modells (Breite x Höhe x Tiefe): | 30 cm x 61 cm x 29 cm | Miniht -Widerstand: | ≥ 10 (pharmazeutisch) oder ≥ 16 MOHM-CM (industriell |

| Produkt Natrium: | ≤ 3 ppb (industriell) | Produkt maximal Desinfektionstemperatur: | 85ºC (185ºF) |

| Produkt maximal Desinfektion Einlassdruck: | 2,1 bar (30 psi) | Produktanwendung: | Mit USP und EP gereinigter Wasser konform |

| Hervorheben: | Veolia E-Cell MK-3 EDI module,pharmaceutical ultrapure water EDI,mini HT EDI module |

||

Produkt-Beschreibung

Das Veolia E-Cell MK-3 Mini HT Elektrodeionisierungsmodul (EDI) ist für die Polierung von Reverse Osmosis (RO) -Permeat zur Herstellung von ultrareinem Wasser konzipiert.Es liefert hochreines Wasser (bis zu 10 MΩ·cm Widerstand)Ideal für die Stromerzeugung, Halbleiter, Mikroelektronik und Pharmazeutika bietet dieses kompakte Modul (30x61x28 cm) einen kontinuierlichen Betrieb.hohe Rückgewinnungsraten (78-93%), und heißwassersanitärer Anlagen

| Durchflussbereich | 0.5·1.6 m3/h (2.2·7.0 gpm) |

| Versandgewicht | 57 kg (126 Pfund) |

| Abmessungen | 30 cm x 61 cm x 29 cm |

| Widerstand | ≥ 10 MOhm-cm (Pharmazeutika) oder ≥ 16 MOhm-cm (Industrie) |

| Höchstsanitisierungstemperatur | 85oC (185oF) |

- Patentierte HT-EDITM-Technologie zur Erzeugung von Reagenzwasser

- 90% geringerer Energieverbrauch im Vergleich zu Mixbed-Systemen

- Wartungsfreier Betrieb mit intelligenter Steuerung

- Echtzeitüberwachung der Leitfähigkeit, des pH-Wertes und des Druckabfalls

- Patentierte, abgestufte Strömungskanalkonstruktion verhindert die Skalierung

Erhält einen Widerstand von über 18,2 MΩ*cm mit einer Energieeinsparung von 22% im Vergleich zu herkömmlichen EDI-Geräten.

- Grundeinheit - Standalone-Reinigung

- RO-EDI Integriert - Vollständige Reinigungsschiene

- GMP-Version - mit vollständiger Validierungsunterstützung

- CE, RoHS, CSA und EAC-Kennzeichnung

- FDA-konforme Materialien

- UKCA-zertifiziert

- Hergestellt in ISO 9001 und ISO 14001 Anlage

- Halal, zertifiziert von IFANCA®

| Parameter | Wert |

|---|---|

| Eingangsdruck | 60,9 bar (100 psi) |

| Maximale Temperatur | 40°C (104°F) |

| Druckabfall | 10,4-2,8 bar (20-40 psi) |

| Erholungsrate | Bis zu 93% |

| Leitfähigkeit | < 117 μS/cm |

| pH-Bereich | 4 bis 11 |

Ideal für Injektionswasser, pharmazeutisches gereinigtes Wasser und Laborreinigungssysteme.

FG Water Technologies ist ein Hightech-Unternehmen, das sich auf die Entwicklung, Herstellung und den internationalen Versand von Wasserbehandlungsanlagen spezialisiert hat.,Nahrungsmittel und Getränke, Chemikalien und Energie.